RAISING-NIBBLING

The olives are picked by hand directly from the trees, preserving the integrity of the fruit and allowing longer storage.

RAISING-SHAKING

The olives are harvested mechanically by shaking the trunk or branches, causing detachment of the olives and the fall of cloth lying on the ground.

STOCKING

Once granted the olives to the mill, preferably in plastic crates perforated to ensure proper ventilation, and waiting to be milled, are stored in cool and ventilated spaces and pressed within 24-48 hours.

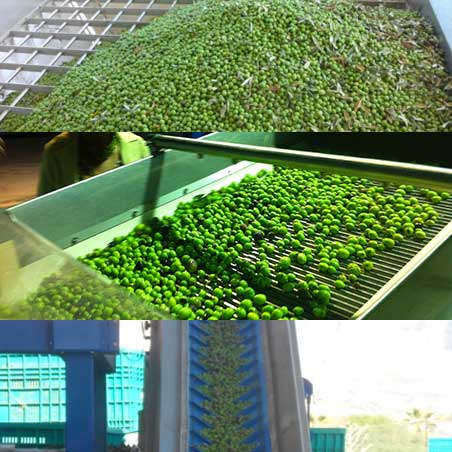

HOPPER-DEFOLIATING-WASHER

Through forklift olives are transferred into the hopper and then to the plant defoliation and washing by means of a conveyor where they are subjected to cleaning by means of suction of the leaves and washing with drinking water.

OLIVEPRESS

After cleaning the olives are then transferred to the hammer crusher where the grinding takes place.

GRAMOLE

The paste thus obtained passes into kneading tanks where a first separation between this and the oil following a "massage" produced by the blades mounted on a rod rotating.

DECANTER

After the step of kneading, then there is a gradual transition to the decanter, where it ends the step of extraction of the oil.

CENTRIFUGE

The oil obtained after extraction with Decanter is conveyed towards the centrifugal separators, through which are eliminated all residual impurities, represented by small deposits of pomace and from the vegetation water.

OIL

The final result of the process: Our delicious oil.